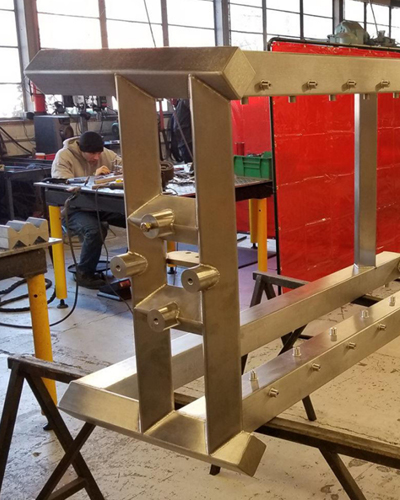

KLT Group has a highly-experienced team of metal fabricators and CNC Machinists that can handle any type of custom or specialty fabrication or machining for small, medium and large sized businesses. As a precision metal fabrication & CNC machining company, we understand the importance of quality, and our team strives to deliver only the finest results. Our services include laser cutting, waterjet cutting, shearing, press brake forming, rolling, as well as MIG & TIG welding, CNC milling, grinding, turning, drilling, boring, and more.

Our team has the knowledge and experience to work with all types of customer requests ranging from large international corporations to a small, independent entrepreneur seeking a prototype of a part to be developed.

We take extreme pride in our track record of supplying quality metal fabrication services that are on time for our customers. Our focus on quality guarantees that all products are manufactured to our client’s specifications.

We offer Precision Metal Fabrication & CNC Machining to Pottstown, and the following areas: Collegeville, Allentown, Limerick, Skippack, King of Prussia, Phoenixville, West Chester, Blue Bell, Plymouth Meeting Valley Forge and surrounding areas. We also service Montgomery, Bucks, Chester, and Delaware Counties. Outside the Philadelphia area, no problem, we service New Jersey, New York, Delaware, Mayland, D.C. Virginia and their surrounding areas. Call today (215) 525-0902

Featured Machine: The Hurco VMX42i

The key features of the Hurco VMX42i that most benefit this particular job are its VMX series of machines and Hurco’s performance series, which offer higher horsepower and torque spindle motors, and heavier, more rigid frames which allow us to run higher federates with accuracy and ease. The onboard part probing allows the machine to accurately check tolerances, tool wear, and reference features for other machined features. Additionally, Hurco’s UltiMotion system allows for an increase in production, shorter cycle times, and improved surface finish due to its systems lookahead and motion control technology. These are just some of the many reasons why KLT Group chooses Hurco CNC machines only.

Hurco VMXX42i | Rough Pass | Material:1018 CRS | Tool:1/2″ Solid Carbide HTC Endmill | Feedrate: 120 IPM @6600RPM | 1″ Depth of cut, No Coolant with Air Blast.

Industries We Service

- Aerospace

- Defense

- Medical

- Commercial

- High technology

- Computer / Electronic

- Retail

- Industrial

- Architectural

- Automobile

- Transportation

- Sports

- Medicine

- Telecommunications

- and more.

Commitment to Quality: ISO 9001 Standards at KLT Group

At KLT Group, our dedication to delivering top-tier CNC machining and metal fabrication services is underscored by our adherence to internationally recognized quality benchmarks. Aligning with ISO 9001 standards ensures that our processes consistently meet customer and regulatory requirements, fostering continuous improvement and customer satisfaction. Whether you refer to it as ISO-9001, ISO 9001, or ISO9001, our commitment remains steadfast in upholding these quality management principles.

Read what our customers are saying…

The KLT group of professional Engineering/Fabrication staff was able to meet for most an unrealistic schedule. Being in a field service division detailed drawings are hard to produce. A phone conversation and a hand sketch were quickly turned into an approved CAD drawing. The needed parts were on time and ready for onsite install. The customer also smiled and nodded when he noticed the “Made in America” sticker on the packaging. Overall great experience. I’ll be back for sure!

-Dave C.

KLT always does a fantastic job! We’ve been working together for years.

Joe B.

We had a rush order for 120 pcs. to correct an issue on-site for a customer in Indiana. It was late Tuesday afternoon, and the item was a brand new design, never seen by KLT, using uncommon material… … Just another day at the office for KLT. The parts were on our customer’s dock at 9:45 A.M. Saturday morning! That’s what makes KLT the “King of Lead Time!!!

– Greg F. Senior Buyer

The team at KLT is in touch with today’s ever increasing demands of the manufacturing world. From quote to delivery, and beyond, you can be assured KLT is there to provide their customers with the absolute best quality, delivery, and price on every piece.